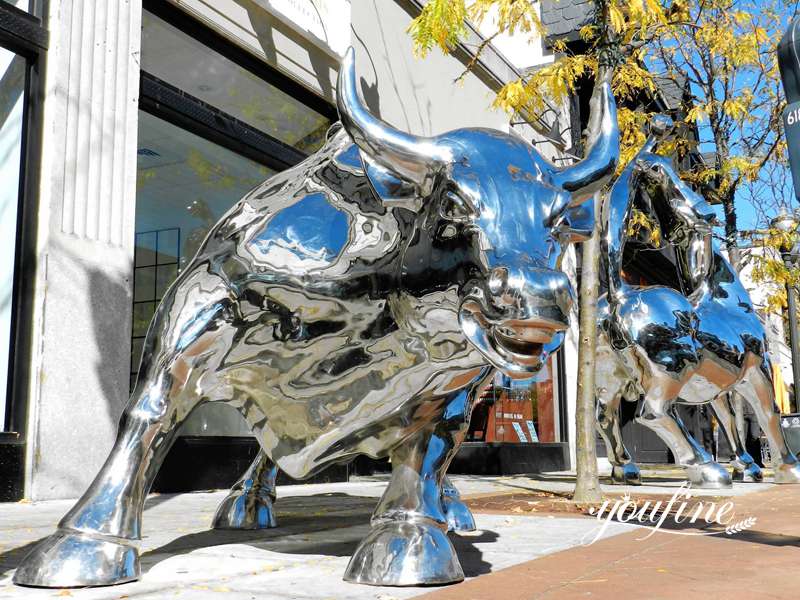

The stainless steel sculpture is inseparable from the decoration of modern space. Many people’s perception of stainless steel is that it will not rust. But in some cases, stainless steel will also produce some spots. Why are there spots on my stainless steel sculpture? Is it because the quality of stainless steel is not good, or is the seller fooling people? In fact, not all of these reasons. There are many other uncontrollable factors that produce spots on the surface of stainless steel.

-

Adaptation of stainless steel model and environment:

Generally speaking, when we make stainless steel sculptures, we use stainless steel cold-rolled plates, which will not rust. However, there are many types of stainless steel models, including 200 series, 300 series, 400 series, and so on. Different models have different levels of corrosion resistance in the environment. If they place in a place with high humidity and high salt content, the stainless steel material selected is not very suitable, and rust may appear. So when you choose a stainless steel manufacturer to buy a modern art sculpture, don’t always ask for the price. Especially if the environment is bad, you have to use better sculptural materials, such as 316. If you use general sculpture materials, rust may appear.

Of course, if the air is relatively dry and the salt content is not great, ordinary stainless steel materials can be used, such as 304. The composition of 304 is 18Cr-9Ni, which is the most widely used stainless steel and heat-resistant steel. Used in food production equipment, nuclear energy, etc. In the general indoor and outdoor environment, the performance of 304 stainless steel is enough to resist the surrounding natural environment. The corrosion resistance of 201 is very poor, so the price is much cheaper. And because 201 contains low nickel, the price is lower than that of 304. If the budget is too low and the sculpture will not be placed outdoors, you can also choose 201. However, for long-term use, it is generally recommended to use 304, the most cost-effective model.

-

The problem of the production process:

In addition to the stainless steel model that will affect the performance of the sculpture, the welding process is also a very important part of the process of making stainless steel sculptures. If the welding is not good, the distance between the solder joints is too large, which will easily lead to corrosion. Therefore, when choosing a sculpture production factory, you should choose a factory with rich experience, a long history, and a guarantee.

-

The problem of stainless steel surface contact:

The rust resistance and corrosion resistance of stainless steel are due to the formation of a chromium-rich oxide film (passivation film) on its surface. Therefore, when the surface of the stainless steel sculpture adheres to containing acids, alkalis, and salts, it will easily cause local corrosion. The surface of the sculpture is stored with dust or foreign metal particles containing other metal elements. And the condensed water between the attachment in the humid air and the stainless steel. The condensed water and accessories form a miniature battery that initiates an electrochemical reaction. Then it will destroy the protective film, which is electrochemical corrosion. Therefore, you must not contaminate your stainless steel sculptures with acids, alkalis or salt substances.

In general, as long as you pay attention to the above three points, your stainless steel sculpture will hardly produce corrosion and spots.

YouFine Sculpture

YouFine Sculpture

Specializing in the production of metal & plastic-based products such as lunch bento boxes and other cutlery etc in India. The group has 4 factories covering 30000 sq. mtr and a network of 50 OEM’s capable of manufacturing a vast range of products in metal & plastics.